LumiReact FLX 3D Printing resin

LumiReact FLX 3D Printing resin

Finally the right resin for your flexible models!

3D printing resin LumiReact FLX.

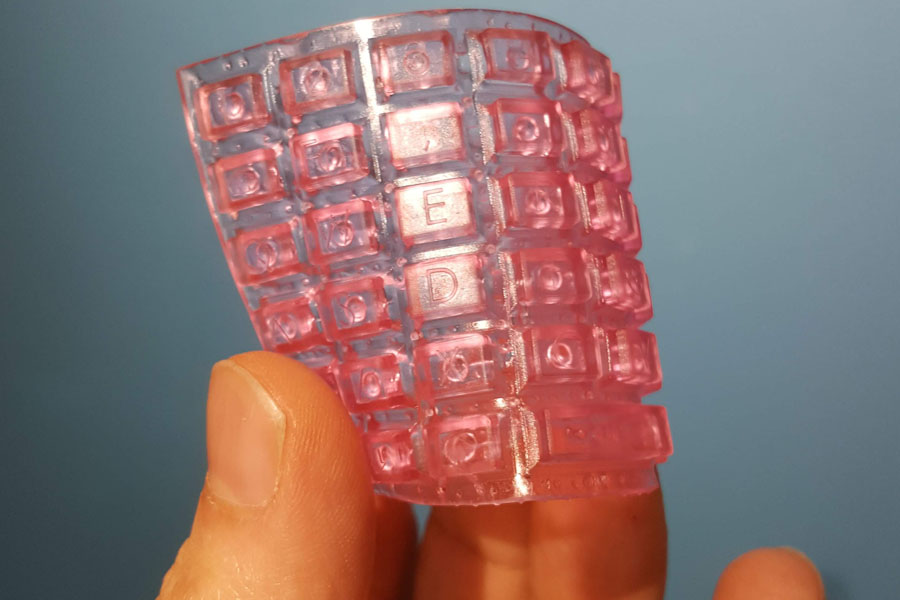

Lumireact FLX has an extremely quick rebound performance and firm compression properties allowing you to 3D print parts that can be compressed.

After long studying and testing, we finally found the right Flexible resin!

It is available in a clear translucent red color in two versions for both SLA and DLP/LCD printers.

To improve interlayer adhesion and bulk mechanical properties, we recommend a slight over-cure of the resin if necessary.

3D printing resin LumiReact FLX characteristics

| Package | 0.5 kg | |

| Color | translucent light red | |

| Viscosity | at 25°C | 1052 cP |

| Glass Transition (Tg) | DMA | 26.5 °C |

| Hardness (Shore A) | 60 | |

| Tensile Strength at Break | D-638-10/03 | 2.7 ± 0.5 MPa |

| Young’s Modulus | D-638-10 | 3.7 ± 0.4 MPa |

| Elongation at Failure | D-638-05 | 87 ±14 % |

| Tear Strength | D-624-00 | 14.9 ± 4.5 kN/m |

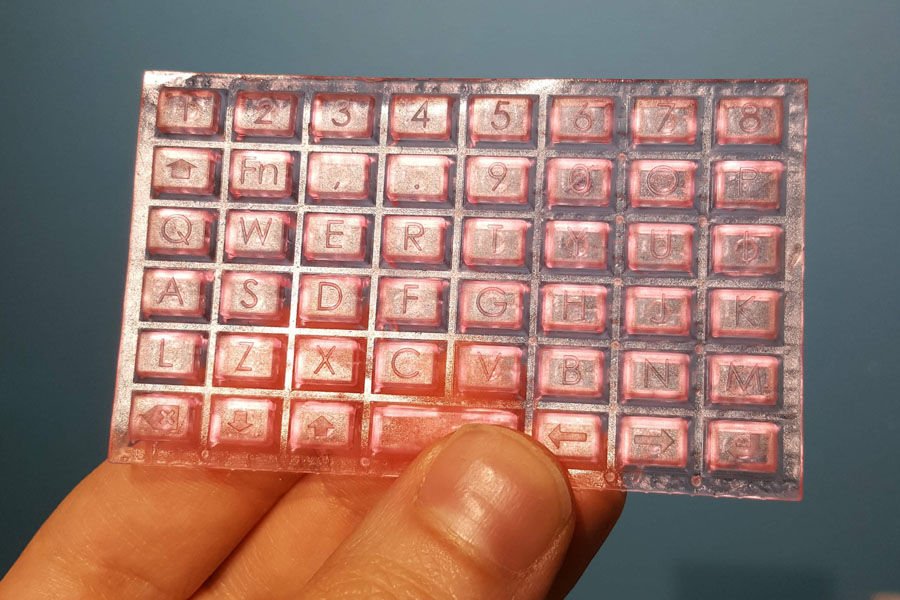

What to print with a flexible resin?

Find out our project for a Flexible keyboard for wearable devices on Hackaday

Finishing Instructions

Lumireact Flex requires post processing and post curing to achieve specified properties.

To clean and remove excess resin, agitate the 3D printed part in an ulkltrasonic cleaner with TEK1969 cleaning or in a simple vat with TEK1960 solvent* for 1-2 minutes until all excess resins has been removed.

Never soak. Use a soft brush if necessary.

Clean off any excess of cleansing liquid with a cold blowdryer or compressed air.

Leave under the sun or in a UV lamp to cure.

Even after full post cure some parts may still have a sticky surface. You can treat your print with Ta-Tack Away. A quick wash in this special formula will add a stick-free coating on the printed part.

Store the resin in a dry, cool, shaded place out of direct sunlight.

General suggested timing on DLP 3D printers*

| Layer Thickness | 50um | 100um |

| Base cure time | 25s | 25s |

| Layer cure time | 5s | 7s |

On Formlabs it is suggested to use Formlabs Clear version 2 (FLGPCL02) setting. Due to the high elongation of the product, care must be taken to ensure good re-lease from the resin tray every layer.

*We cannot test our resin on every single 3d printer model. Please use this timing as a starting point to find the correct curing time on your ow 3D printer.